[ad_1]

Compost Bin Plans

Material I Used to Build The Compost Bins:

Step 1: Building the posts for the Compost Bins

I have a set of plans for this larger size I made myself but I also have a set of plans that is smaller. Since I live on land and have a huge garden, I wanted the extra capacity. I’m placing this right outside my garden, next to a potting shed I built a few years ago. I’m going to skip digging holes because that’s standard practice but know there are 8 needed for this build and a 4×4 can be placed in each one. The back posts are simply cut to size, then plopped in their spot.

The front ones, have a center channel that runs most of the way down. These are what make the front slats adjustable. To cut these in, I go to the table saw. A trick to cutting in the channel easily is to set up two fences. I make my first pass by using the table saw fence which is set up to establish the far right boundary of the channel.

On my second pass, I use a scrap straight board that is aligned to the left of the needed channel. Another scrap is placed on the outfeed table to establish the depth of the channel. When it comes time to run the third pass, I don’t use either fence, but instead float my 4×4 in between the two to clear out as much of the center as I can.

Don’t worry if you don’t get it all though, a chisel can do the rest of the clean up work. Typically when working with a chisel, you want to use the big flat portion to move along the wood. However, in situations like these where the handle prevents you from getting down flat, know you can flip it over and use this small bevel instead. It’s a smaller surface area so it’s harder to keep flat, but just place a finger or two down on it to help.

Step 2: Preparing the Posts to be Placed in the Ground

Ok, with the channels made, lets put these posts in their place in the front line up. With posts going in the ground, make sure you’re using pressure treated wood. In fact, I recommend using Prowood which even has labeling to help you pick out the correct treated material for your specific project. For my posts, I made sure to find the label that said “ground contact”.

One of my favorite things about Prowood is they use the latest advancement in pressure treated lumber to color treat their wood! So instead of the standard green tone, you can now choose from a variety of colors and skip the staining step. The wood is color infused so pigment is driven deep into the wood fibers that’s warrantied to stand up to the elements for years

Step 3: Placing the Posts in the Ground

Let’s move on to setting these posts in the ground. I didn’t feel like messing with concrete so for this project I used decomposed granite as an alternative. This stuff can be found bagged in the garden section. On every post, I fill the hole up about 1/3 of the way, then I tamp it down, aka compact it.

To get it started I prefer to use a short scrap and I chose a 1x so I can fit into the tight spots around the posts. I’m going for enough compaction to keep the post from leaning a ton so that I have both hands to place a level on one side of the post and push it into plumb. Once I have it there, I compress more, then repeat on the other face of the same post. After getting it just right, I fill up the hole further then really try my best to compact it tight.

I have a rock bar, because everybody in the hill country does, and it actually comes with a 2” round tamp on one end, so that’s what I use.

I recommend you start with an end, then hop down the line to set the other end post, then knock out the in betweens. More than making sure each post is plumb on two faces, you also want to make sure the faces are square to one another, I’m using that long 1×4 to test this.

Step 4: Leveling the Posts

Next I made all the compost bin posts level to each other. To do this, I found the height of the shortest post, then cut the top off the others posts to match it. I did this with two passes using a circular saw. This is faaaaar easier than trying to get all 8 holes exactly to the same depth.

While I was cutting, I cut in a shoulder on all four of the back posts. Be watchful because if you move around a post as much as I did here, you’lI absolutely have to replumb it. A good tip is to don’t be too worry about perfectly plumb until now, just get it close, because the next step is to add a 2×4 that reaches across all four of these back posts to secure them together.

At this point I made sure the posts were perfectly plumb then I could tamp away and compact it as much as I could.

Step 5: Adding Screening to the Compost Bin

Go ahead and take your time on setting these posts because if they are plumb and square, then it will make everything else from here fly. The next step is to dress off the back of the compost bin. There are a few options you could go with for screening but I recommend hardware cloth. I’m using a crown stapler to pin it into place, trying to work out the bubbles as I go. I pin it in just a few places to hold it down, then once I don’t have to hold it any longer, I go back and thoroughly attach it. I imagine there will be a decent amount of pressure once these compost bins are full.

To cut hardware cloth you can absolutely use a pair of side cutters but a much faster way is to use a right angle grinder with a cut off wheel. Don’t worry if you get into the wood a bit.

Step 6: Cutting Railings for the Compost Bin

At this point I go back to my shop and cut some rails that will span from the back posts to the front ones. I use my bandsaw to cut in two different shapes on one end of these pieces. The T’s will be placed in the center, while the Ls will be placed on the outside. On all of these, I start by attaching the back of the rail to the back post. When I move to attach the front, I move the rail in or out with my knee. Things should be plumb at this point, but each one was slightly off. No problem though, After pinning it in front, I could once again tamp down the granite.

Step 7: Hardware Cloth for the Compost Stalls

With these rails in place you can see the shape of each stall appearing. To complete it, I wall it in using hardware cloth on all the inside faces. These are roughly cut to size first to make handling them a little bit easier, but once I start pinning them, I let them run long on the front because it’s easy to trim perfectly to length after. In fact, if you have a buddy around, have them grab a pair of square nose pliers and pull the hardware cloth tight while you secure it. This is most useful on the front home stretch.

Note: that this air gap in between each stall is intentional. Airflow is a big contributor to a healthy compost pile that won’t stink. If you do compost right, which includes air flow annnd a balance of brown and green layers, then odor shouldn’t be an issue.

Step 8: Walling off the Front of the Compost Bin

Alright, lets wall off the front. To keep the bottom slat from resting on the ground, I ran in a screw to interfere with the track on the 4x4s. This means, I can now feed in slats as tall or as low as I want for each stall. I’ll probably leave them all high while filling and letting the compost cook, but it will be very useful to take off slats as I’m removing the compost for use.

Note: treated wood vs. non-treated wood

if you’re worried about using treated wood around compost know that the main ingredient in Prowood pressure treated lumber is actually copper, which is used in frying pans and even water lines. The technical name is Micronized Copper azole which still makes the wood termite and fungal resistant but means you can use it on food prep surfaces. It also means other benefits like it’s more natural looking, less corrosive to fasteners, and color treated boards will outlast cedar and redwood boards, hands down.

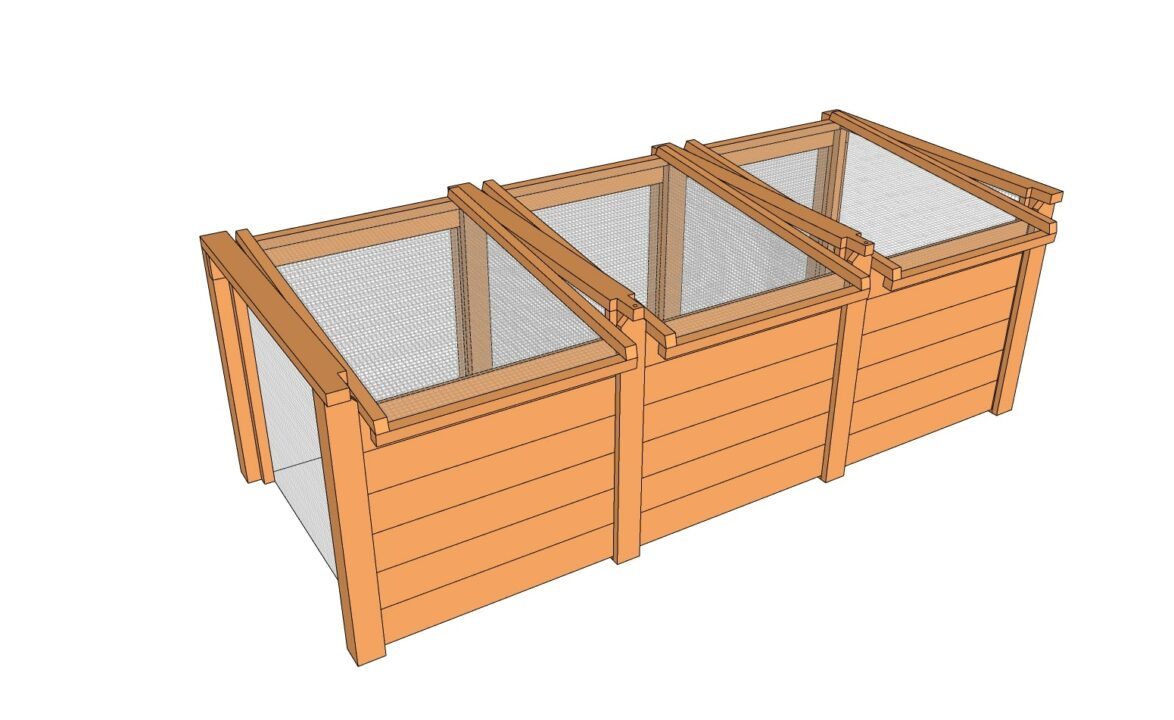

Step 9: Protecting the Compost Bin by Adding Lids

Ok one last component and this compost bin project will be a wrap, in order to keep animals out, next I built some lids. These are pretty simple construction with some 2x2s and more hardware cloth. I built these inside my shop because it’s way easier to do on a large surface than on the ground.

I started by attaching the cloth to one of the 2x2s, then flipped it over and attached the long side to this short side. Then just repeated on the remaining two sides. Again, going for air flow but a no critter zone.

To attach them to the compost bin, I started by screwing on a few hinges to the back of the body. Then I set the lid in place, lined it up to this hinge then secured it with screws. Regardless on how long you have the front wall, this lid will close down but lets go ahead and install all the slats and take a look.

You can absolutely leave it as is but I installed a simple string attachment with a small weight in order to make lowering the doors a little easier. And you’re done! You’ve built your own compost bin!

I am just now getting into composting so I know I don’t know much, but I think this three section compost bin rock! There are three bays because there are three stages of composting. I’ll always have one that I’m filling, one that is in the cooking stage, then one that will be ready to use compost. It will be close to two years before I have this third ready to use but once I invest the time, I should always have a stall rotating into use.

The front wall is super easy to lower, or raise depending on the task that’s needed, the lids will keep animals out but lets in moisture and airflow, and unlike compost methods that require tumbling, I’ll be able to layer up green and brown things to let sit until ready. It’s a super low maintenance compost bin.

****Remember I have a set of compost bin plans if you would like to build your own. I have this set which is large, but also the same design on a smaller scale. You can also go to prowoodlumber.com and find out where to buy Prowood for your next build. **** I’ll see you on my next project!

Additional Things I Used in this Build

[ad_2]

Source_link