[ad_1]

Even if you’re not an electrician, you probably know that electrical wires are made from copper.

However, you may have also heard of aluminum wiring, and you may have heard that it can be dangerous.

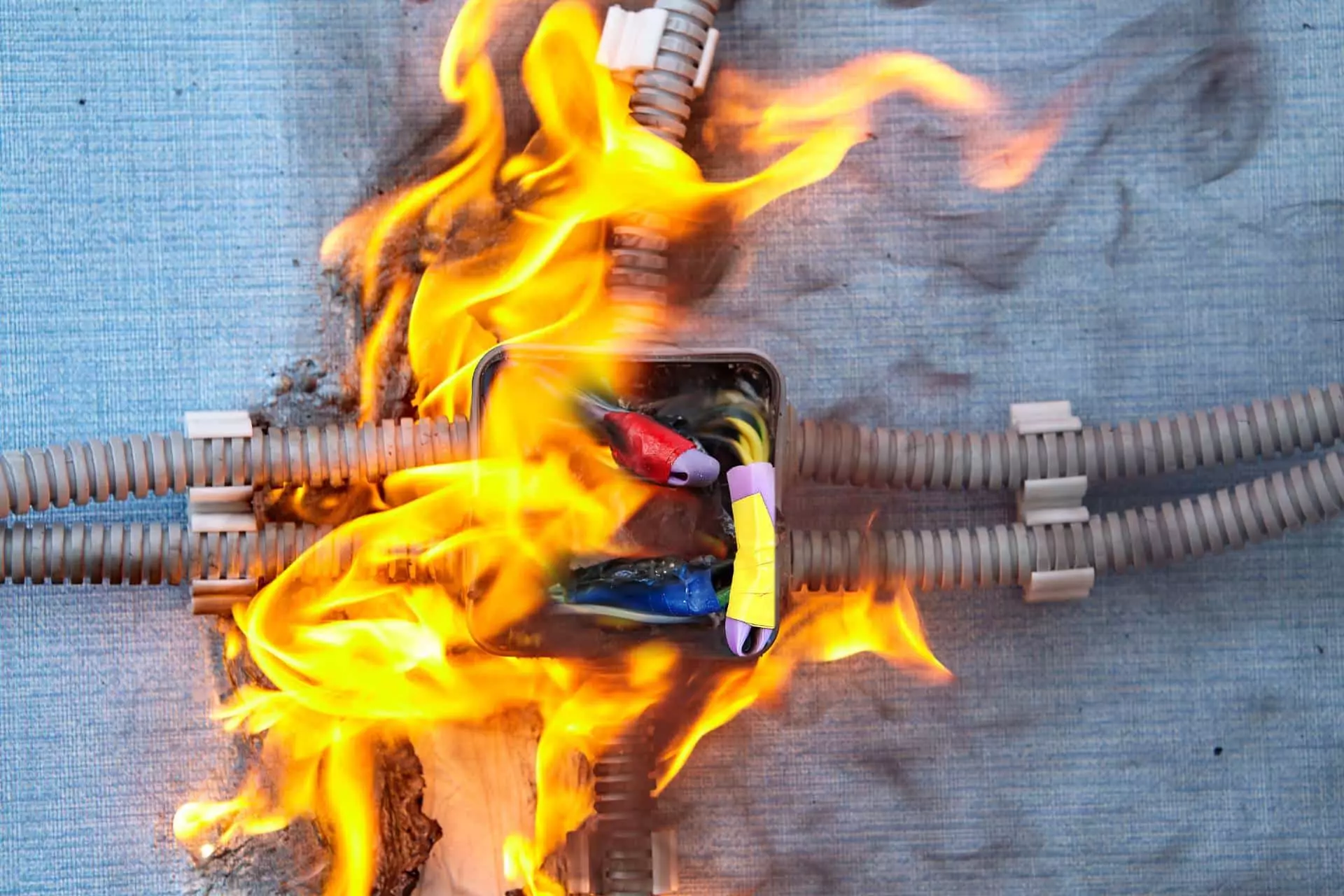

In a home with aluminum wiring, there is an increased risk of fire hazard conditions.

Aluminum wiring can often be found in homes built in the 1970s and 1980s, and your insurance company may require that any homes with aluminum wiring be addressed with acceptable repair by a trained electrician.

Naturally, this is a concern for both homeowners and home buyers.

If you are in the process of buying a home, any aluminum wiring should be noticed during your home inspection.

Of course, any home inspector is not infallible.

There’s always the possibility of missing aluminum wiring on a home inspection.

But you don’t have to rely on your home inspector.

With a little knowledge, you can learn to identify aluminum wiring yourself.

You can understand the risks and hazards, how to conduct aluminum wiring repairs, and how to make a home with aluminum wiring safe.

As always, it is best to contact an experienced electrician when working with electrical wiring.

⚡ Why Was It Used, and Why Is It Dangerous?

You may think aluminum is a flimsy metal that would likely melt if used as an electrical wire.

It’s true that aluminum is not as good a electrical conductor as copper wiring, so to make aluminum wires safe, they need to be somewhat larger than copper wires.

However, if aluminum wires are large enough, they can handle their rate of electrical load without overheating.

But if copper is ultimately a better conductor and aluminum wire has to be bigger, why use aluminum?

With so many things in life, it comes down to cost.

Even after making aluminum wires larger, they are still cheaper than copper.

For this reason, in the 1970s and 80s, the industry tried to change over to aluminum wiring.

The result was increased electrical fires.

If aluminum wiring is ultimately safe, where does the danger come from?

The answer is the point of connection between the wired and any device it is powering (such as an outlet or light switch).

Unless they are specially manufactured, most common electrical devices will use copper connection points.

It is the connection between two dissimilar types of metals that can be dangerous.

As electricity flows, the wire heats and cools over time due to the electrical current.

At this point of connection, where the aluminum wiring connects to a copper terminal screw, it is possible dangerous overheating can occur.

It is this overheating that makes aluminum wiring dangerous.

At these hot spots, loose connections can occur.

Aluminum is a softer metal than copper.

As the aluminum conductors heat and cool, and the aluminum expands, potentially working loose the connections.

And, of course, loose wires can be a fire hazard with either aluminum or copper wires.

⚡ How To Identify Aluminum Wiring

? Outer Wire Jacket Markings

All wiring is required to be labeled clearly on the outer jacket.

The abbreviation for copper is CU, and for aluminum, it is AL.

If the wires running into your electrical panel are visible, you can safely examine them and find these markings, and easily determine if you have a mix of aluminum and copper wires.

If the wires aren’t visible or the markings aren’t clear, you must open the panel to identify any aluminum wiring.

? Ground Wires In The Panel

You should be able to visually inspect your branch circuit wiring in your electrical panel.

If you are uncomfortable or not experienced with electrical work, contact a licensed electrician.

Before opening your electrical panel, set your main breaker to the Off position.

This will kill power throughout your entire home.

When you remove the exterior cover, you should see a smaller panel covering the service compartment.

Do not remove the service compartment cover, as these wires will always be live.

With the main breaker turned off, the breaker compartment will be dead.

In the breaker compartment, you should see a set of ground lugs.

These will be a set of screw terminals mounted to the interior body of the electrical panel.

The ground wires from every circuit will be on these ground lugs, and the ground wires are bare, with no insulation.

This makes looking at the ground wires an easy way to see what type of metal your wires are made of.

Look over the ground lugs, and if you see any wires that are a silver color, you’ve got aluminum wires.

If you’ve confirmed that you have some aluminum wires, you must ensure that any possible fire hazards have been mitigated.

There are a few options, but if you aren’t experienced with electrical work, it is best to contact a professional electrician.

? Evidence Of Electrical Problems

The aluminum wire may have already resulted in dangerous situations in homes with aluminum wiring.

If you notice any burned insulation, either in your electrical service panel or at any wiring device binding terminals, then your aluminum wire has already become very dangerous.

You should contact a licensed electrician immediately to repair or replace your aluminum wire.

⚡ Heavy Loads and Approved Devices

In some circumstances, the aluminum wiring is perfectly safe and acceptable in a home.

The most common is with any larger electrical appliances.

The majority of circuits in a home are 15 amp circuits.

Almost all electrical devices which use a higher amperage are manufactured with connection points that are safe for aluminum wiring.

If you have aluminum wiring on circuits larger than 15 amps, for example, an electric range oven or dryer, this is probably not a concern.

However, you can confirm that your device is compatible with aluminum wiring.

The connection points may be labeled as “CU or AL,” indicating that they allow for either copper or aluminum wiring, but if such markings are not visible, then you should contact the manufacturer.

⚡ Replacing The Wires

The idea of an electrical wire catching fire within your walls is possibly a homeowner’s worst nightmare.

Upon discovering that you have aluminum wiring, you may be inclined to remove them from your walls as soon as possible.

Removing all aluminum wiring and installing new copper wiring is obviously the most thorough and best solution.

Unfortunately, this undertaking will probably be as difficult and expensive as you imagine.

Most likely, your walls and ceilings will need to be cut open.

For this reason, most people don’t take this route unless they are already doing expensive renovations.

If you’re willing to go to the time and expense needed, fully replacing any aluminum circuits is a perfect solution. In your house, this may not be a practical solution.

⚡ Copper Pigtails

Thankfully, the nightmare of wires catching fire in the walls isn’t realistic.

Aluminum wiring itself is a perfectly capable conductor of electricity.

The danger areas are where the aluminum wiring is connected to a terminal point which either isn’t aluminum or isn’t capable with aluminum.

When two dissimilar metals are connected together in an electric circuit, the point at which they meet will often have higher electrical resistance than the rest of the circuit.

Over time, this point may become dangerously hot, and that’s when it becomes a fire hazard.

Because the points of connection are the areas of danger, it’s possible to make the circuit safe simply by fixing these points.

And so rather than replacing the wires altogether, your goal is simply to make the connections safe.

At each point where an aluminum circuit is used, you can splice on copper wire and use this wire to connect to the device, whether that be an appliance, an outlet, a light fixture, or switches.

To eliminate galvanic corrosion between two dissimilar metals, the copper wire must be spliced to the aluminum wiring properly.

This is a process called pig tailing.

First, cut a pigtail of copper wire, and use a pair of pliers to twist it with the aluminum wire.

You should not need to use a special crimping tool for this process.

Then cap the splices with wire nuts.

However, to prevent aluminum oxide, the twist-on connector must be filled with anti-oxidizing gel.

This can be purchased in most hardware or electrical stores, and special connectors come pre-filled, sometimes called alumiconn connectors or copalum connectors.

Once you’ve twisted the wire, fill the wire nut with the anti-oxidizing gel, then twist it on the splice.

There are also specially made wire nuts for this purpose which come prepared with the gel.

This copper pigtail can now connect safely to the device, such as light fixtures or light switches.

Once all connections on an aluminum circuit have been spliced with this pigtail method, the danger has been mitigated.

Although almost all circuit breakers allow for aluminum and copper, you will have to use the same pigtail method in your panel if your breaker is not rated for aluminum.

Sometimes, simply identifying all the places where a circuit is used throughout your house can be difficult. If you’re not sure, contact an electrician.

⚡ Final Thoughts on Aluminum Wiring

Aluminum wiring can be concerning, particularly in homes wired in the 1970s and 80s.

In any home with aluminum wiring, it poses a potential hazard, but it’s not something you need to panic about, and you don’t have to rely on home inspectors to identify aluminum wiring.

With some basic knowledge, you can understand the dangers, evaluate possible solutions, and determine a course of action to help make your family and house safer.

Evaluating aluminum wiring and addressing the dangers requires someone experienced in electrical work.

As always, it’s best to contact an experienced local electrician when working with electricity.

Want to learn more about your home’s electrical system? Feel free to check out our other electrical articles!

Related Reading: Top 10 Common Home Electrical Problems and Solutions

[ad_2]

Source_link