[ad_1]

Let’s Build an Outdoor Storage Bench!

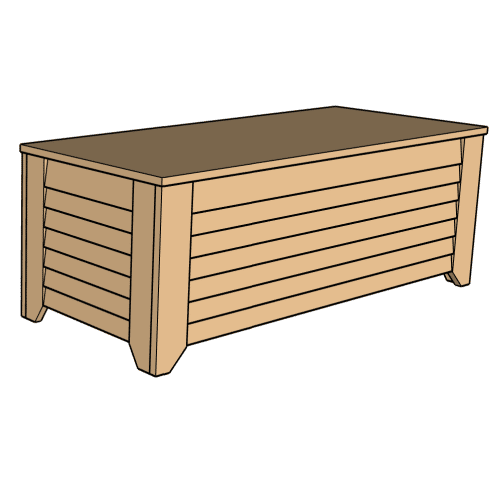

DIY Storage Bench

$9.99

You can go a lot of different ways for material for this storage bench but I went with an exterior rated MDF called Armorite. I know, I know, it’s typically a cardinal rule that you can’t use MDF in situations where it could get wet, as standard MDF swells and is forever ruined. Just look at how much that expanded? This Armorite is not only moisture resistant but is also treated with zinc borate to resist rot and termites. plus it machines so clean compared to standard MDF, this is straight off without any sanding.

I’ve created a set of build plans to help making building your outdoor storage bench simple.

Materials I Used to Build the Outdoor Storage Bench:

Step 1: Organizing Storage Bench Parts and Pre-Drilling

I first organized my parts on one of my work areas before getting started. To start the storage bench assembly, I first join together the front to one of the sides. Since this project will be going outside, I’m using an exterior wood glue on all the joints then pre drilling and running in a screw. I place my pieces near the end of my workbench so that I don’t have interference with my drill when pre drilling. After getting the first side connect, I repeated to connect the other.

Step 2: Placing the Bottom Between the Storage Bench Walls

Now before attaching the other side, I’m going to slip in the bottom, this should fit perfect between the two short sides. Once in place, I run around the three sides and add in screws to attach it. With that done, now the final fourth side of the box can be added in the same way. Nice and easy. Keep in mind that I’m making mine for outdoor but you can make yours into a end of the bed bench or a keys toy chest, or anything where you need decorative storage.

Step 3: Adding Legs to Get it off the Ground!

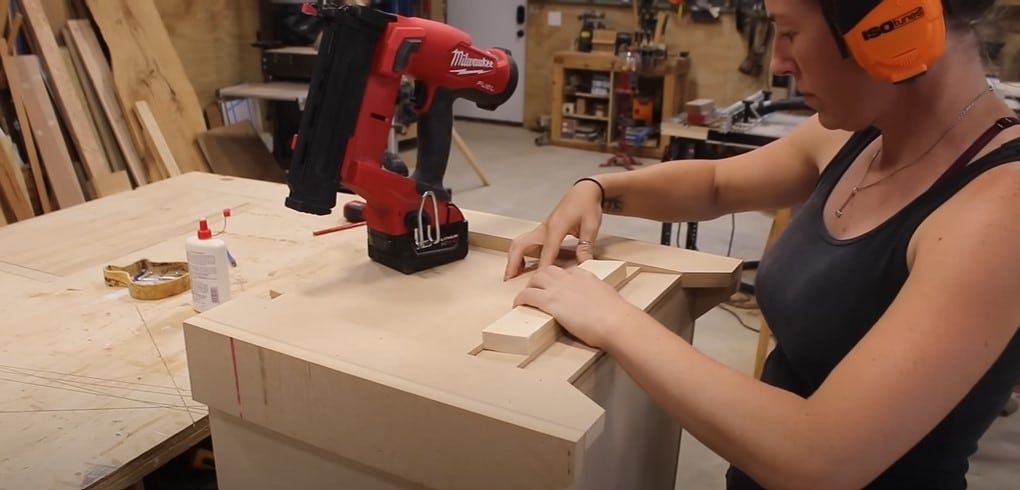

The storage bench body is done. Lets add some legs to it. Everything is made from Armorite and to distinguish the legs some, I took all the pieces to the miter saw first to cut in a slight angle. Now they can be added to the body. Two pieces will make up the leg, one is narrower than the other so that both look the same width once they are attached. I’m using wood glue once again but now switched over to using 1 1/4” brad nails instead of screws. In order for the legs to come out looking the same width, they need to be attached properly. Meaning the small side needs to be placed on first.

Well while I’m fixing my mistake I might as well show you a tip to remove brad nails. Instead of clipping them, which never leaves them perfectly flush, I like to pull them out on the backside. I do this with the large set of Crescent’s square nose pliers. I get a good grip on it then roll the nose so it pulls the nail up straight. Sometimes it breaks, but it’s easy to get another grip and pull it the remainder way.

Step 4: Placing the Side and Decorating the Body

With the short side in place, now I can butt this one right up flush and everything will come out looking correct. Another way you can do it is by placing the unit on it’s head, yeah actually this way is much easier, as you have the workbench as a reference point for both of them instead of holding one up while trying to get it flush to the top.

Lets stand it up and take a look. Yes, perfect.

Noooow, lets tilt it back down in order to decorate the body. I’m going with a lap siding look. This is very easy to achieve. You can start off with a small strip piece down at the bottom, this will create a bump off for the first siding strip. For everything on this step I’m using a little bit of wood glue and brad nails.

Actually, I’m going to go ahead and lower this to the floor as it’s just high enough to be annoying….or maybe I’m just short enough. This will be much easier to see and use my nail gun at this height but now I just need to grab one of my rolling around stools.

Step 5: Attaching the Long Sides

Ok to start attaching the siding, this goes quick and easy. I laid down the first strip so that it’s flush with the trim piece below. From there, each strip is cut to fit in between the legs so that’s easy to get right but the overlap amount can vary. To make sure they all come out consistent, I cut a spacer. Now I just have to line this spacer up to the bottom side of the previous strip then nail it in place. I move this spacer over to the right and repeat. Then to the center and repeat.

With it stuck in place, I throw in a few extra ones in between before moving on to the next and repeat the process again. When you’re shooting in brads, keep in mind the over lap that each board will have and make sure to place your brads in this zone. That way the next board you lay down will cover up the nail hole. Oh I don’t know if I mentioned before, but the entire body is made from 3/4” but the slats I made from 1/4”. Armorite comes in varying sizes, I’ve even used 1” before on projects.

Something else to talk about on this step is adhesive. There is just a corner of the slat making contact to the body so you can’t use wood glue. You’ll want to switch to construction adhesive and my go to for projects is DAP Dyna Grip. It’s rated for interior or exterior and a small bead in a few places under each new slat works great.

Step 6: Attaching the Short Sides

After I got the long side complete, I flip the unit up on end and repeated with the short side. That’s another distinction with Armorite it takes brad nails so much cleaner than standard MDF. You don’t get that mushrooming and chipping.

Now, down we go and lets have a look. Well, that is pretty darn cute. And so quick!

Step 7: Placing the Top of the Storage Bench

Lets keep the momentum going by adding the top. For my lid I went with a plane slab of MDF because I plan to have cushions on it for sitting. But know you could always cut in a cool patten or make it look like individual boards like I show how to do on an outdoor cabinet. I’ll link that for you below. I line up the top to the body so that it’s flush on the back then pre drill and attach the hinges.

Step 8: Painting the Storage Bench

Worked like a charm. Note that I didn’t add a handle or cut one in because there is a built in lip that’s easy to grab all along the front. Let’s break all of these edges and get ready to throw a coat of paint on it! I actually did an entire video on how to properly paint MDF so I’ll link to that below if you’re interested. You can definitely roll or brush on paint, but since I have an HVLP, that’s what I used to really get in all the nooks and crannies, easily.

After letting it dry I moved it into place and tested it out. Since I knew I would be sitting my bench up next to the house, I left the lid as is, but another option is to add a chain to catch the lid from opening too wide if you are placing it somewhere without a wall. I can sit the cushions in place, but then when I want to stow them away, I can simply open the lid and put them in until next time.

All in all, this project only takes about two hours to complete once the parts are cut. So it’s nice and simple but will create a decent amount of storage for a variety of different spaces. Remember that I have a set of plans and a CNC cut file if you’re interested in building your own.

[ad_2]

Source_link